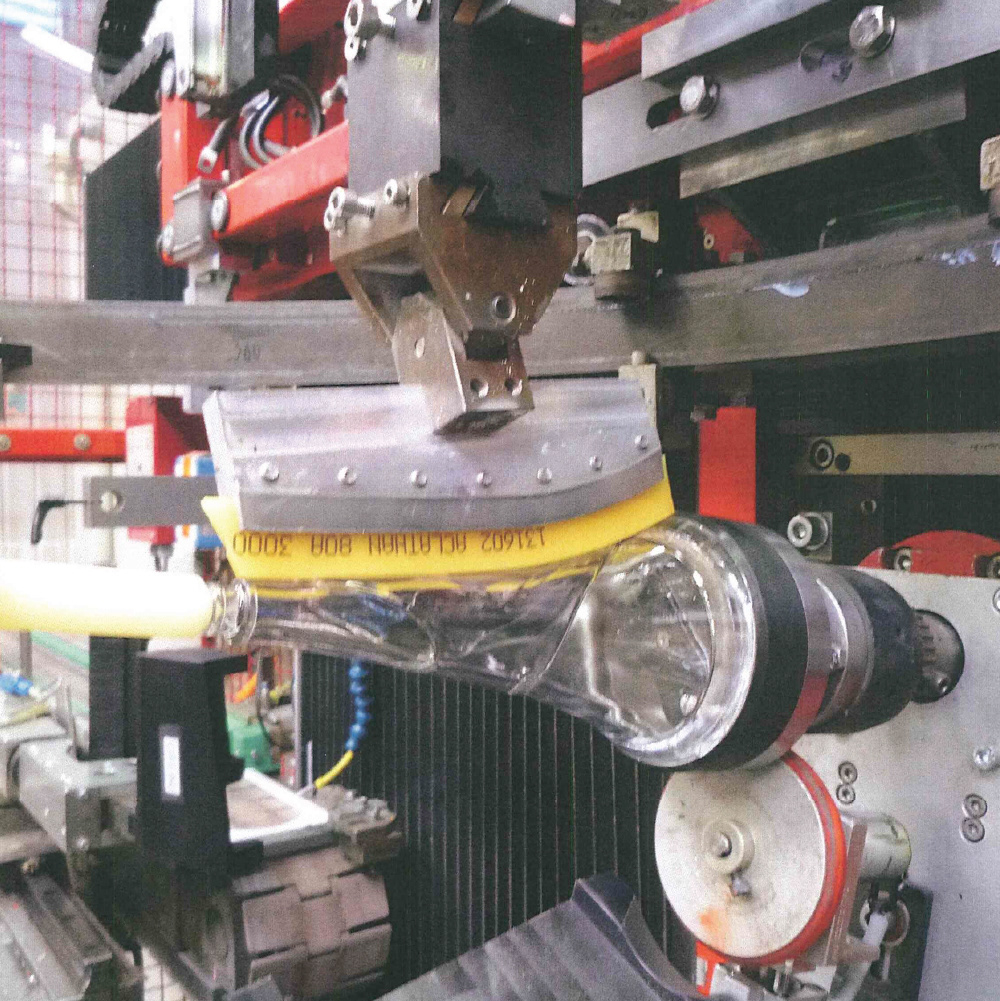

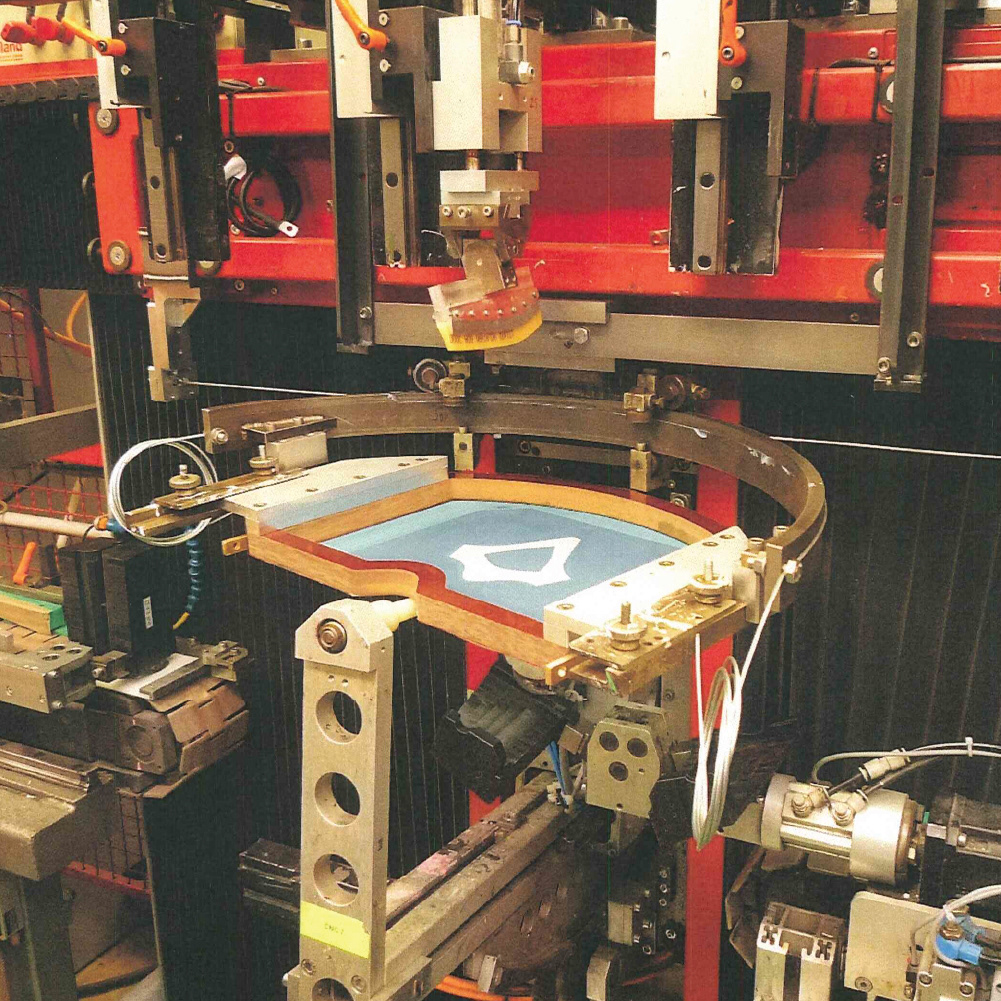

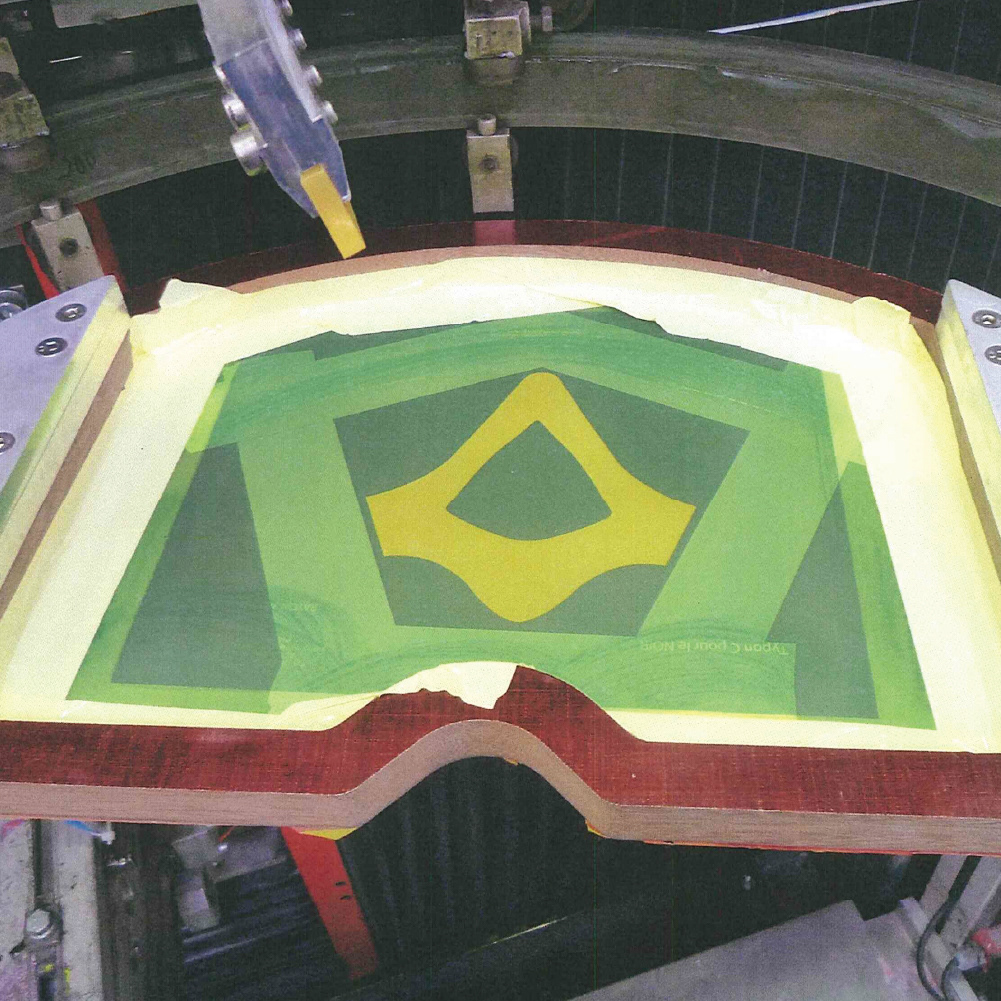

Multi-pass CNC screen printing, requiring 20+ iterations to achieve luxury packaging standards on complex, curved geometry.

THE CHALLENGE

Complete high-precision decoration for celebrity luxury fragrance bottle featuring complex curved geometry. Two-pass application required exact overlap registration and custom seam modifications to prevent ink dripping on vertical surfaces. Extensive testing, 20+ iterations, and close collaboration with print specialists, ink lab, and client were essential to develop production-ready artwork that met luxury packaging standards for a high-profile launch.

DESIGN APPROACH

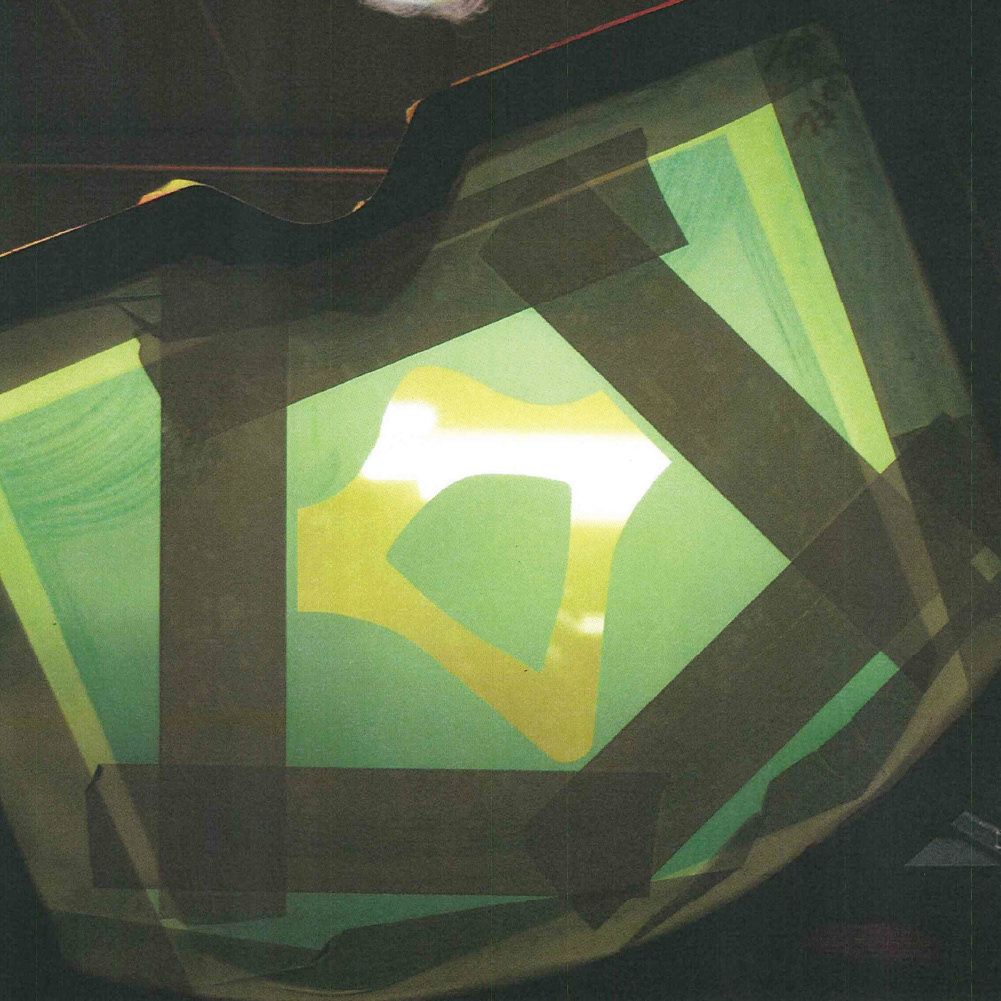

Directed artwork development from concept through 20+ test iterations to production launch. Process required hands-on problem-solving: adjusting seam wrapping based on ink viscosity testing, sizing pass layers for precise registration, and mapping artwork to complex curves. Close collaboration with print specialists and ink lab enabled rapid refinement cycles, with each test informing the next revision until luxury brand standards were achieved.

THE OUTCOME

Successfully launched for celebrity luxury fragrance line, contributing to over $80 million in first-year product sales. The bottle remains in active production today, maintaining precision and quality standards across ongoing manufacturing runs. The project demonstrated the effectiveness of iterative testing and close cross-functional collaboration in solving complex curved-surface decoration challenges.

Key Results

Supported $80M+ product launch success

Continues in production with consistent quality standards

Successfully developed production-ready artwork through 20+ test iterations

Demonstrated effective collaboration across print specialists, ink lab, and client teams

ONE OF MANY

This project represents one of hundreds of precision projects completed during my tenure at SGD North America. Each required the same level of detail, iterative refinement, and cross-functional collaboration. This particular bottle is featured because of its high-profile nature and technical complexity, pushing the boundaries of what our facility could achieve on curved glass surfaces. The problem-solving approach, attention to precision, and commitment to quality were consistent across all projects.

More examples of bottles to come!